Nutrien recognized by National Safety Council for two safety initiatives

Nutrien’s commitment to safety was recognized twice in 2022 by the National Safety Council (NSC) – employee Paul Gray was named one of the 2022 Rising Stars of Safety and Nutrien Ag Solutions was a finalist for the 2022 Green Cross Safety Advocate award.

Paul Gray: Nationally recognized rising star of safety

For Safety Coordinator Paul Gray, there’s no end to safety – each day is only as good as the one before.

Paul’s continuous improvement mindset is what sparked an idea during a discussion with his Safety, Health and Environment (SHE) manager. They realized there was a missing piece to the safety management system at Nutrien’s Carseland, Alberta Nitrogen facility.

The solution has improved the safety of work at the site and earned Paul recognition as one of the NSC’s 2022 Rising Stars of Safety.

“We have robust systems in place to identify and address low- and high-risk potential hazards, but there was no formal process for risk that ranks between those categories,” explains Paul. “That’s why I saw the need to develop a pre-job hazard assessment process that is based on the fundamentals of a job safety analysis and hazardous energy recognition.”

He spearheaded the development of the pre-job hazard assessment (PJHA), which creates a systemic hazard recognition structure consistent for every job or scope of work. Instead of only focusing on task-specific hazards such as welding or grinding, the PJHA process also accounts for the type of energy exerted in each step of the task.

A multidisciplinary group comprised of a facilitator, subject matter expert, operators and representatives for the trades, safety and engineering thoroughly reviews the scope of the job and focuses on the energy type at each stage in order to identify and mitigate potential hazards.

The PJHA process is how we do things the Nutrien Way – identifying possible hazards and mitigating them before work begins helps support and sustain the safety of our teams and operations.

Retail proud to be finalists for national safety award

The Nutrien Ag Solutions team is proud to have been a finalist for the NSC’s 2022 Green Cross for Safety Advocate award for its Retail Training Center in Rosthern, Saskatchewan.

While Nutrien wasn’t chosen to receive this year’s statuette, being in the final three is still a huge honor – particularly after Nutrien won the award last year for its ammonia program.

“Being acknowledged by the NSC for the second year in a row proves that Nutrien is leading the way in safety,” says John Horne, VP, SHE. “The Retail Training Center was an important investment to provide our employees with safety courses and to provide a place where people across our industry can gather to make agriculture safer.”

Nutrien challenged the status quo and moved away from its traditional approach to safety training for Canada and is now leading the region with a first-of-its kind training facility.

The center has a large outdoor area that can be used for classes when weather permits. Inside, there are two classrooms and a physical training space where scenarios are set up to provide hands-on experience.

It offers nine high-risk and life-critical operations training courses, on topics including fall protection, confined space entry and energy isolation. Employees can also take Serious Injury and Fatality (SIF) prevention classes, including advanced anhydrous ammonia training. Making this course more accessible for Canadian employees was one of the main inspirations behind this project, as ammonia is one of the most hazardous materials Nutrien Ag Solutions employees have to handle. Along with in-person classes, the center also hosts virtual training sessions on topics like mental health.

“The Nutrien Way is the daily actions each of us can take to stay safe. At our center, we provide coaching to empower employees to use their stop work authority,” says Henry Ens, Senior Manager of SHE for Retail in Canada. “We demonstrate what unsafe situations look like, the proper personal protective equipment that should be used, and how to implement what is learned in day-to-day operations.”

Related stories

Explore more about Nutrien

Sudeepta Mohapatra loves the thrill of the chase

In my role I track the global agricultural fundamentals that help in predicting short to long-term trends driving the future direction of the global agriculture industry. I also develop and update various economic models. These models are used to estimate and predict crop input expenditure in our [...]

Read more

Nutrien Releases 2023 Global Community Impact Report

Nutrien’s Community Relations & Investment (CRI) supports our business purpose by nurturing communities through collaborations with community partners who share our values and help us to make a positive and lasting impact in the communities where we operate. “While we share CRI data and stories [...]

Read more

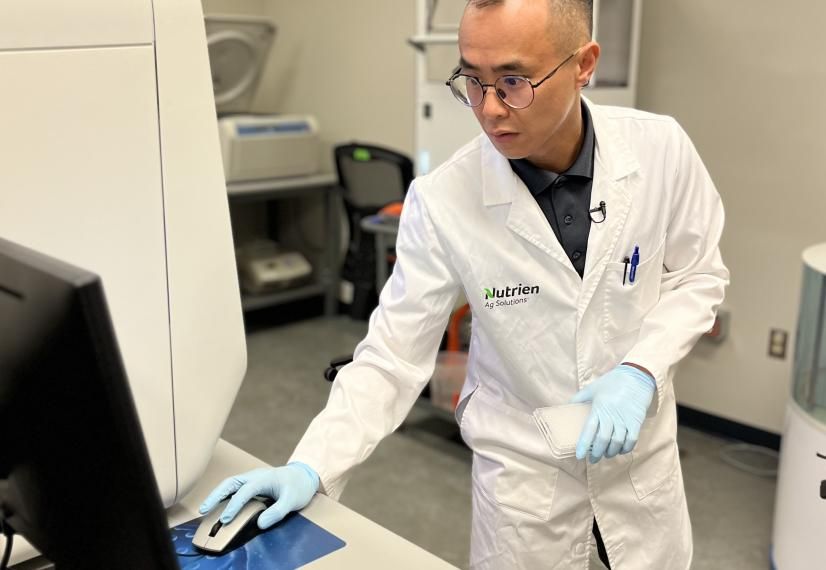

Using DNA analysis to make more resilient crops

Did you know that Nutrien has a Genotyping lab? It’s located in our Canola breeding facility in Saskatoon, Saskatchewan. Employees like Li Tan, Lead, Molecular Biology, work in the lab to analyze DNA for specific genes within plants.

Read more