Solid as NROC – using tech to raise the bar on production efficiency

We’re establishing a new operations center that will improve troubleshooting, monitoring and optimization across our Nitrogen facilities, and significantly enhance safety, reliability and efficiency.

The teams who work at Nutrien’s nitrogen production facilities are experts at leveraging the power of collaboration – they routinely share knowledge and learning across the network so they can duplicate each other’s successes and avoid each other’s challenges. But with help from our central engineering and digital technology teams, they’re establishing a new operations hub to integrate, automate and optimize that work – and raise the bar on its effectiveness.

Work began last year to establish the Nitrogen Real-time Operations Center (NROC) in Loveland, Colorado, to monitor, troubleshoot, and optimize Nutrien’s 10 major nitrogen production facilities.

“NROC is designed to reduce the time our facilities spend not producing or producing less than their full capability,” says Trevor Williams, Interim President, Nitrogen and Phosphate. “It will do this by detecting failing equipment sooner, identifying the root causes of failures more quickly, and enhancing the monitoring of equipment so sites can run closer to optimum operating points.”

Let there be NROC

NROC is envisioned as a team of experts – specialists in each of the six major workstreams that drive a nitrogen plant, plus a team of digital experts focused on data science, machine learning and technology design – who work in close daily collaboration with each other, and with site operations.

So far, the systems to support one of those workstreams is in place – and operations, engineering and digital technology teams are working to establish the others in the months to come, with a goal of having the center fully staffed by the end of 2024.

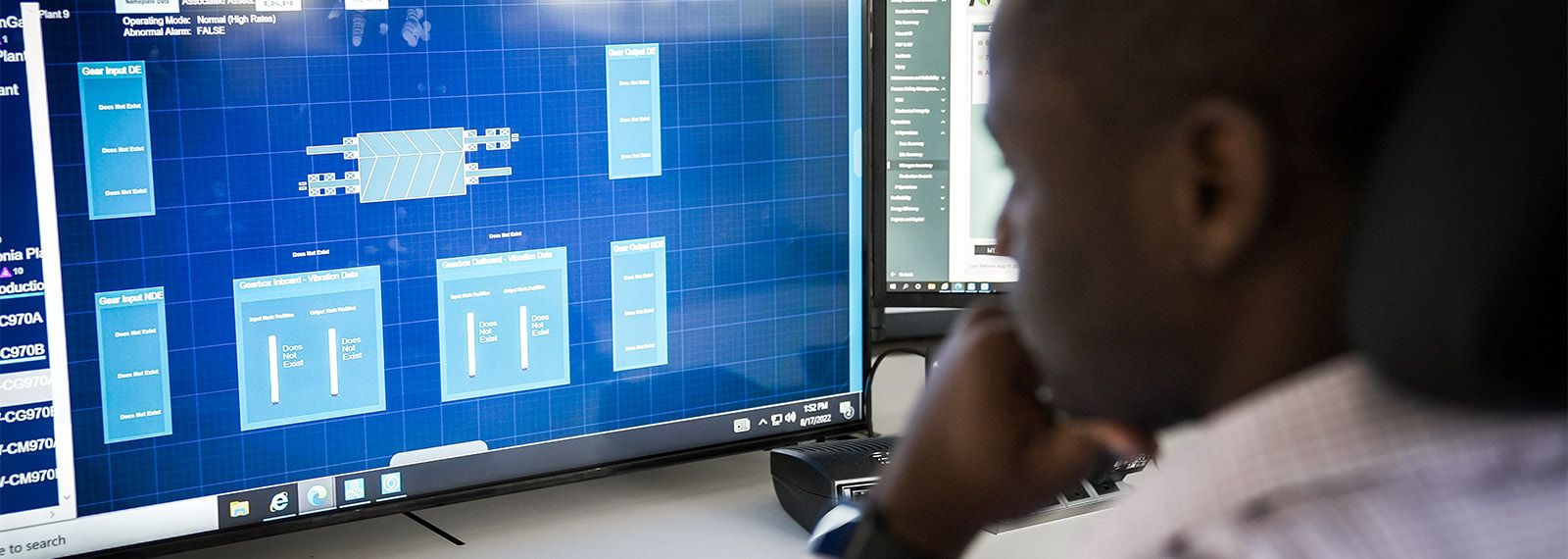

A robust technology platform, accessible via a high-tech, multi-screen workstation, has been established to monitor and analyze data related to the nitrogen sites. It provides access to all relevant sensors and measurements across the company, asset description and simulation information, new scalable strategies for detecting failures in advance, and fast access to all of this by a centralized domain expert.

Creating a secure and reliable pipeline to securely provide this enormous volume of data in close to real time was a huge challenge, and then customizing the systems and interface to enable the expert to access and effectively process and analyze this data was an enormous lift – and it required ingenuity, openness and collaboration from the operations, engineering and digital technology teams.

“There’s infrastructure in Loveland that we needed to build, there's infrastructure to support the connectivity, and infrastructure to support the groundwork behind the curtains to make sure everything works,” says Gary Peterson, Director of IT for Nitrogen & Phosphate at Nutrien. “Then there’s a bit of a culture change that has to happen at the sites, where there’s a shift in the way we’re working. From our Information and Digital Solutions team to Engineering to Operations, we’re navigating this change really well so far – but really, we’re just getting started.”

TJ Heidrick, Special Projects Manager for Nitrogen at Nutrien, is excited about NROC because it will help raise the bar on monitoring and data analysis, as well as collaboration.

“The toolset we’re establishing is bigger than what can typically be developed at a single site, because we’re able to leverage specialized knowledge and technologies at a multi-site scale – and include all sites simultaneously in the conversations,” TJ says. “NROC will also provide an extra set of eyes that is familiar with site equipment and has easy access to its design information and current operating status – and that can be a big help to site operations during key moments.”

NROC on…

While 2024 is the date Gary and his colleagues and counterparts are working towards, even when NROC is fully staffed and established, it won’t ever really be “done,” because growth, adaptation and optimization are hardwired into its DNA.

“The foundation and infrastructure we built for NROC will be used across our company. And within NROC, everything has been built with scale and further development in mind as we continue to grow and learn from our successes,” he says. “Our priorities are to develop technologies that leverage existing technology and data investments through integration, and to mix the new-and-novel with the tried-and-true, to target effective improvements to the safety, reliability and efficiency of our operating facilities. It’s a big task, but a noble vision – and we’re having a lot of fun bringing it to life.”

Related stories

Explore more about Nutrien

Sudeepta Mohapatra loves the thrill of the chase

In my role I track the global agricultural fundamentals that help in predicting short to long-term trends driving the future direction of the global agriculture industry. I also develop and update various economic models. These models are used to estimate and predict crop input expenditure in our [...]

Read more

Nutrien Releases 2023 Global Community Impact Report

Nutrien’s Community Relations & Investment (CRI) supports our business purpose by nurturing communities through collaborations with community partners who share our values and help us to make a positive and lasting impact in the communities where we operate. “While we share CRI data and stories [...]

Read more

Using DNA analysis to make more resilient crops

Did you know that Nutrien has a Genotyping lab? It’s located in our Canola breeding facility in Saskatoon, Saskatchewan. Employees like Li Tan, Lead, Molecular Biology, work in the lab to analyze DNA for specific genes within plants.

Read more